Cable insulation inspection behind the instrument panel.

TÝKÁ SE / CLARIFICATIONS: Cable insulation inspection behind tha instrument panel.

DATUM VYDÁNÍ / DATE OF NOTICE: 30.4.2019

DATUM ÚČINNOSTI / EFFECTIVE DATE: immediately, imperative before the next flight

OMEZENÍ / LIMITATIONS: Not applicable

OVLIVNĚNÉ VÝROBKY / AFFECTED PRODUCTS: TL 2000 Sting S4 serial numbers

VÝROBNÍ ČÍSLA OVLIVNĚNÝCH LETADEL / AFFECTED SERIAL NUMBERS: All serial numbers

ČÍSLO BULETINU / NOTICE ID: 5.S.ST.2019

ČÍSLO NAHRAZENÉHO DOKUMENTU / SUPERSEDED NOTICE ID (if applicable): -

POČET STRAN / PAGES: 3

OPATŘENÍ / CONDITION:

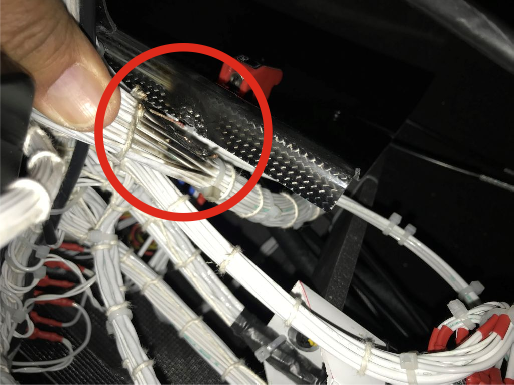

During the operation of the TL 2000 Sting fleet, there was a disorder caused by a break in the wiring harness insulation followed by a smoke smell. The damage of the cable insulation occurred at the point of contact of the cable harness with the edge of the composite central interior column in the area behind the main dashboard. The wiring harness is gradually touched with the central column edge due to the operational vibration of the airplane.

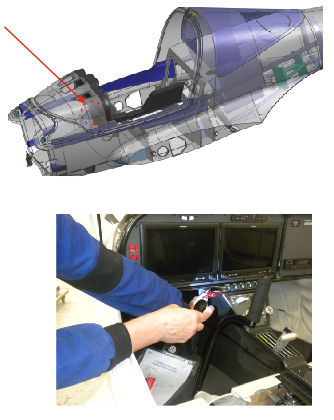

To remedy the potentially unsatisfactory status of TL-UTRALIGHT proposes to perform an immediate inspection of the wiring harness condition and instrument panel for the entire fleet of operated TL 2000 Sting S4 in order to prevent a possible cause of fire or future damage to airplane equipment. In order to provide the inspection, the dismantle is not necessary or usage of any special tools (it is enough to find the right source of light). Such inspection could be performed by aircraft operator only.

INSPECTION STEPS:

1) Airplane preparation

Shut down and brake the airplane (ideally in indoor areas). Secure chassis wheels with chocks. Make sure the airplane's main switch is in the off position. Secure the rescue system activation handle (locking pin). Remove the upper motor cover and disconnect the battery (+ pole).

2) Status Inspection

Check the cable harness behind the instrument panel with a special focus on the harness transition area to the central interior column. The area is accessible from the airplane cabin. Use a suitable light source for inspection.

Make sure there are sufficient clearance (min. 10mm) between the wiring harnesses and other parts of the airplane and that the wiring harnesses are fastened in such a way that contact cannot occur even during the airplane operation.

If the inspection reveals wiring harnesses with insufficient clearance, clearance must be ensured. Cable harnesses can be retrofitted by adding additional electric fasteners.

3) Completion

Reconnect the battery and install the engine bonnet to complete the airplane. Verify the functioning of any electrical equipment that may be affected by inspection or repair of insufficient clearance.

4) Airplane logbook record

Record the execution of a binding service bulletin in the airplane logbook in the following forem:

The binding service bulletin 5.S.ST.2019 has been implemented. Minimum clearance between wiring harnesses has been detected / assured.

Datum: Signature:

NOTE

In case that the operator fails to ensure the performance of this bulletin, any damage to the airplane or its equipment caused by failure to perform the bulletin will not be accepted as a complaint by the manufacturer.