Retractable landing gear and carefully thought through design are the key aspects behind unforgettable performance of the TL-2000 Sting RG. Astounding speed range is turning this aircraft into a higher category machine.

We have kept the impeccable design and features of the Sting S3 and added on speed and climb performance – that is how this smoothly elegant sportster came to being. Wherever the Sting RG appears, all eyes follow.

After great success of the Sting S3, our desire to push speed boundaries, without compromising safetyhas driven us further. Of course, all of this had to be packaged in a beautiful sleek design so typical of our TL-ULTRALIGHT aircraft. We had turned our attention to landing gear and have developed a steadily retractable mechanism, with which we fulfilled our dream. Thanks to the courage and our desire to try new techniques, we have achieved our goal. The Sting RG is an epitome of speed, safety and elegance. The Sting RG´s speed range is overwhelming, its flying qualities normally belonging to machines of higher categories. The Sting RG has outdone itself. It will become the highlight of its owner´s personality.

Maximum comfort for both pilot and passenger. Increased luggage space. Easy cabin opening and access.

Sufficient space and devices that you can comfortably reach to. Dashboard in front of the passenger has been tilted for improved pilot´s view. You might appreciate cabin heating or convenient handles for easy cabin opening to name a few.

We are able to customize the cockpit, including device fittings according to client´s specific wishes and requirements.

Choose from classic analog instruments or opt for a combination with modern dislays. Wide selection of various radio types, GPSs and many other safety and pilot devices are a given. The choice is up to you...

Even in the area of steering and control we have focused on maximum safety and comfort. The Sting RG will exceed your expectations.

Features: full dual control, classically arranged sticks, adjustable foot pedals for steering, retractable tricycle landing gear – main wheels with brakes, steerable nose wheel, flaps – at 15 ° for take-off and 35 ° for landing

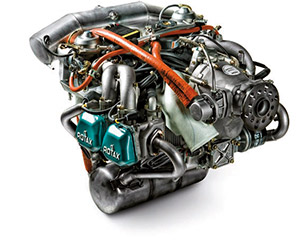

The Rotax 912 ULS is a four-cylinder, four-stroke engine, with liquid cooled cylinder heads and air-cooled cylinders. It has got a dry sump forced lubrication with a separate oil tank of 3 liters, automatic adjustment by hydraulic valve tappet, 2 carburetors with constant pressure in the diffuser, mechanical fuel pump, contactless electronic dual ignition with two circuits, electric starter and propeller speed reduction unit i = 2.43.

The Rotax 912 iS was developed on the basis of the 100 hp Rotax 912 ULS engine. The main difference between 912iS and 912 ULS is substitution of carburetors for preparing mixture with dual, electronically operated fuel injection system. Other changes include oil pump reinforcement and increase in generator performance.

It is a four-cylinder, four-stroke engine with liquid-cooled cylinder heads, air-cooled cylinders, dry sump lubrication with a separate oil tank, automatic adjustment by hydraulic valve tappet, electronic dual fuel injection, electronic engine management (EMS), electric starter, propeller speed reduction unit and an engine suction system.

The Rotax 914 is a four-cylinder, four-stroke engine with liquid-cooled cylinder heads and air-cooled cylinders, with a turbocharger and a pressure relief valve. It has got dry sump lubrication with a separate three liter oil tank, automatic adjustment by hydraulic valve tappet, two carburetors with constant pressure in the diffuser, mechanical diaphragm fuel pump, contactless electronic dual ignition, electric starter, propeller speed reduction unit i = 2.43 with overload clutch, motor mount, suction chamber and stainless steel exhaust.

The PowerMax is a three-blade tractor in flight adjustable aircraft propeller. The aluminum alloy hub consists of top and bottom flange with lid. The blade adjustment mechanisms are located inside the hub. Increasing of the blade angle is done by the actuator. For the opposite direction, the blades are adjusted through the resistance of spring located inside the hub. The carbon fiber blade has got an aluminum alloy root part and is mounted onto the hub by a pair of axial bearings. The actuator is located outside the hub, above the engine reduction unit, and controls the blade adjustment by a hollow axis of the reduction unit and the propeller.