Focused on comfort. Sport flying or long business flights are both fitting for the Sirius.

When designing the Sirius, we have put our focus into bringing you cockpit that is spacious and modern, providing maximum comfort for the passengers. During your first minutes in the air, the Sirius is capable to demonstrate its unsurpassing flying qualities to you. Signature TL on this aircraft means that you have made the right decision.

Behind the TL 3000 Sirius – the high-wing carbon composite aircraft from TL Ultralight – stands the experience of more than 700 of its low-wing siblings, the Star and the Sting. We have put all of the acquired experience into it. To this, ideas of larger cockpit with ultramodern equipment, unlimited aircraft view and surprisingly large luggage compartment have been added. We even considered comfort for well-built pilots! This will be especially appreciated during longer business trips. The Sirius has set a new benchmark in comfort and ergonomics. That is why it is the TL-ULTRALIGHT champion in its category. If quality, comfort and style are your priorities, you will go for the Sirius...

Only Sirius can provide ample cockpit space. High level of comfort even for well-built passengers. The luggage compartment will surprise you. Large windows, allowing for maximum view and easy cabin access will certainly win you over.

Cabin heating and heated seats option are just the beginning. Optional add-on features can turn your Sirius into a limo that you will not want to leave.

We are able to customize cockpit in order to fit client´s specific needs and requirements, including instrument furnishing. Choose from classic analog instruments, or go for a combination of modern displays. Wide selection of various radio types, GPSs and many other safety and pilot devices is a given. The choice is up to you…

Complete dual yoke control and well thought through placement of control devices will turn your piloting into an ultimate experience that you will not want to stop talking about. Safety, as with all of our aircraft is an absolute given. 3D Vizualization

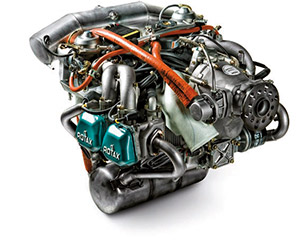

The Rotax 912 ULS is a four-cylinder, four-stroke engine, with liquid cooled cylinder heads and air-cooled cylinders. It has got a dry sump forced lubrication with a separate oil tank of 3 liters, automatic adjustment by hydraulic valve tappet, 2 carburetors with constant pressure in the diffuser, mechanical fuel pump, contactless electronic dual ignition with two circuits, electric starter and propeller speed reduction unit i = 2.43.

The Rotax 912 iS was developed on the basis of the 100 hp Rotax 912 ULS engine. The main difference between 912iS and 912 ULS is substitution of carburetors for preparing mixture with dual, electronically operated fuel injection system. Other changes include oil pump reinforcement and increase in generator performance.

It is a four-cylinder, four-stroke engine with liquid-cooled cylinder heads, air-cooled cylinders, dry sump lubrication with a separate oil tank, automatic adjustment by hydraulic valve tappet, electronic dual fuel injection, electronic engine management (EMS), electric starter, propeller speed reduction unit and an engine suction system.

The Rotax 914 is a four-cylinder, four-stroke engine with liquid-cooled cylinder heads and air-cooled cylinders, with a turbocharger and a pressure relief valve. It has got dry sump lubrication with a separate three liter oil tank, automatic adjustment by hydraulic valve tappet, two carburetors with constant pressure in the diffuser, mechanical diaphragm fuel pump, contactless electronic dual ignition, electric starter, propeller speed reduction unit i = 2.43 with overload clutch, motor mount, suction chamber and stainless steel exhaust.

The PowerMax is a three-blade tractor in flight adjustable aircraft propeller. The aluminum alloy hub consists of top and bottom flange with lid. The blade adjustment mechanisms are located inside the hub. Increasing of the blade angle is done by the actuator. For the opposite direction, the blades are adjusted through the resistance of spring located inside the hub. The carbon fiber blade has got an aluminum alloy root part and is mounted onto the hub by a pair of axial bearings. The actuator is located outside the hub, above the engine reduction unit, and controls the blade adjustment by a hollow axis of the reduction unit and the propeller.